Stroboscope Techniques

Monarch Instrument, Inc. is a world leader in the manufacture of digital stroboscopes tachometers, vibration meters and paperless recorders. Our precision instruments have been used for 30 years throughout industry to increase production, ensure the quality of finished goods and troubleshoot equipment. The Stroboscope is a powerful diagnostic tool with uses in predictive maintenance, production, quality control and research. Stroboscopes allow “slow motion or stop action” visual inspection of rotating, linear or reciprocating objects.

Trouble‐shooting Belt Driven Systems

Our machine is a fan, belt‐driven by an electric motor. As the unit is running, tune the Stroboscope to the operating frequency (running speed) of the drive pulley/sheave. Visually stop the motion. Inspect the belts and sheaves for signs of wear, cracks and frays. Read the exact part numbers if replacement is required.

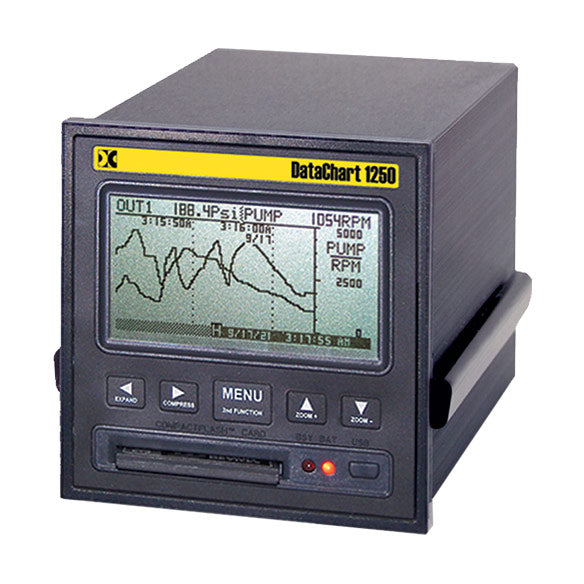

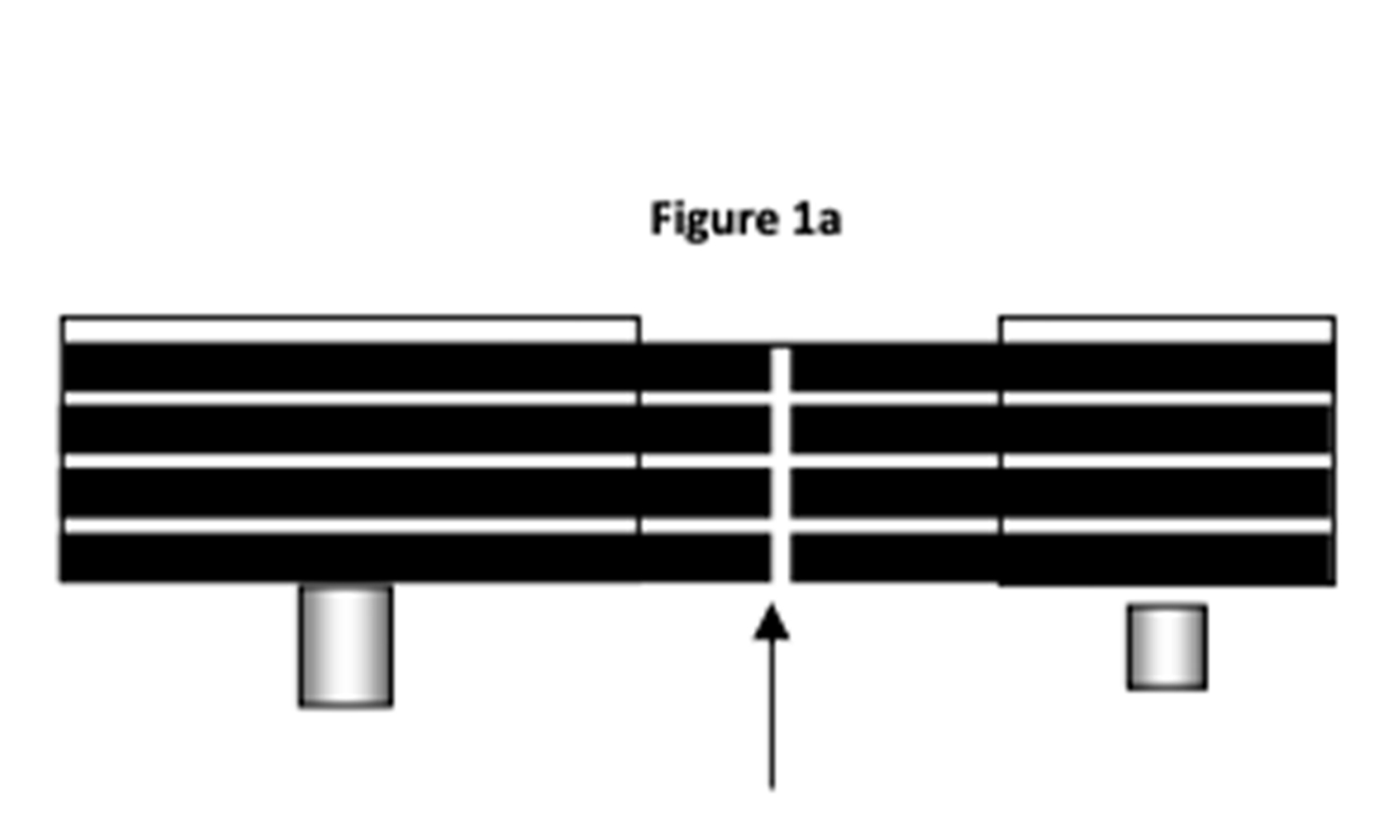

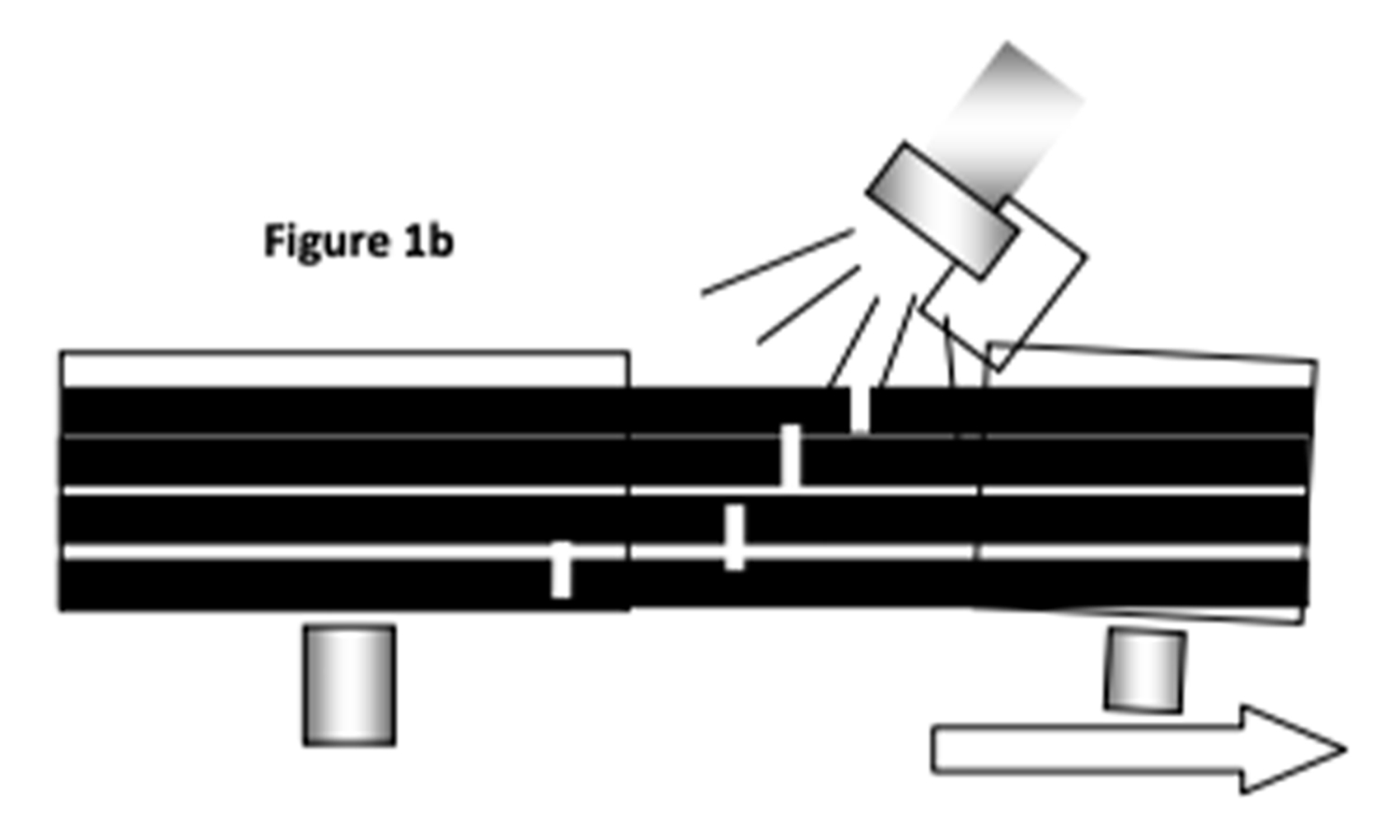

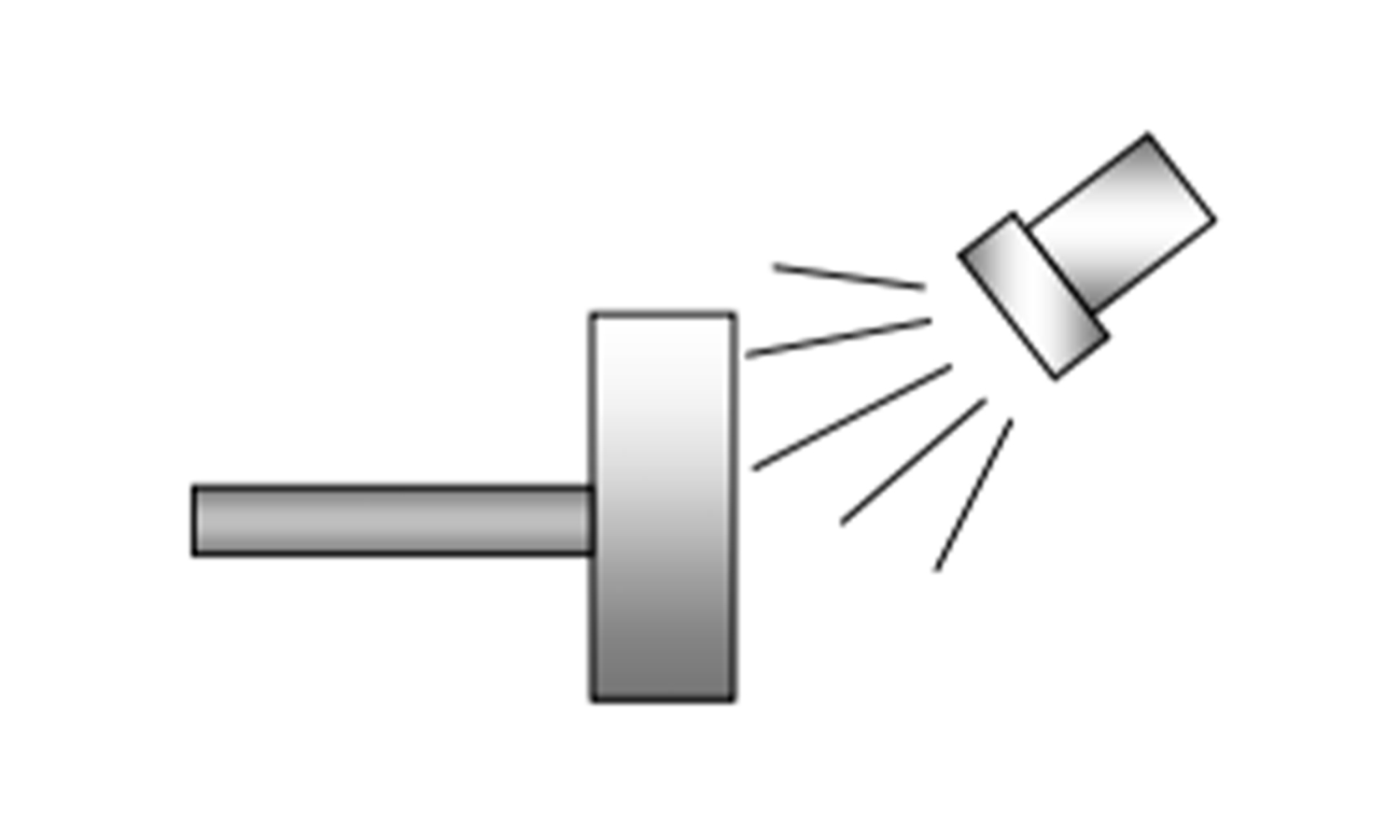

If you are able to shut the fan off, use chalk or a paint stick to draw a line across all the belts (figure 1a). Draw another line along the entire edge of the outboard belt (figure 2a). Safely start the machine. Again tune the stroboscope to running speed, now observe which belts are actually pulling the load (figure 1b). You should be able to spot the loose and stretched belts immediately.

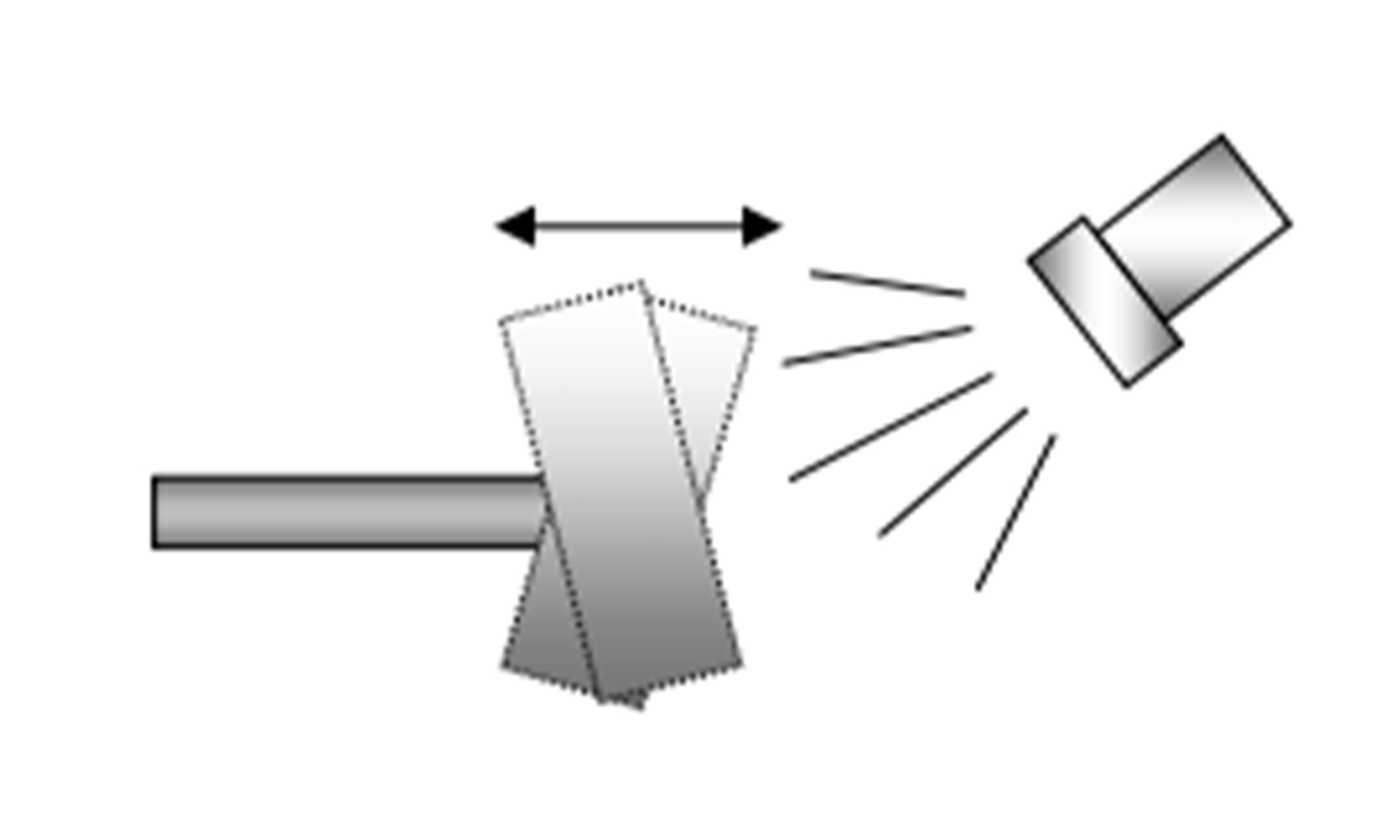

Next, slightly de‐tune the stroboscope, say 50‐100 cpm (rpm), and observe the outboard belt. If it draws a shape similar to a peanut (figure 2b), check your sheave alignment of the unit.

With the machine off, draw a reference line across all the belts. Re‐start the machine and observe the reference lines. If the alignment is good the lines should remain as pictured.

Flash the stroboscope tuned to exact running speed. As seen in the figure, the outboard belt is pulling the load due to misalignment. The mark can be seen at running speed. Each progressive inboard belt is slipping and the marks lag behind and move slower than running speed.

Stop machine. Place chalk on outer edge and slowly hand turn the sheaves. This will leave a mark the entire length of the belt.

As the machine runs, tune to running speed. Slightly de‐tune stroboscope and view belt profile. If the peanut shape is observed, check alignment.

Can’t Shut It Down?

To check for belt slippage without shutting off the unit: Tune the stroboscope the exact running speed of the sheave you want to inspect, carefully view the belts at the sheave. The belts and the sheave should all appear stopped. If there is any slippage you will see a belt slowly creeping while the sheave is “frozen.”

Taperlock Sheaves, Finding Bent Pulleys, Shafts and Blades

Many belt systems make use of the taperlock bushing on the sheave. Because unequal pull on the installing bolts can cause these sheaves to “tip”, use the following technique to check for axial concentricity. Tune the stroboscope to operating speed and observe the sheave. Next, double the speed of the stroboscope and observe the maximum displacement of the sheave. If the sheave appears to move a great deal, check the run‐out with a dial indicator and re‐align the sheave. This method will work for any rotating component when checking for maximum displacement. Belts, bent pulleys, bent blades and bent shafts may be observed with this method.

Actual Running Speed 1500 rpm.

Side view.

2x Actual Running Speed 3000 rpm.

Observe maximum displacement or wobble.

Proper Tuning

Stroboscopes should be used with caution. For safety, inform those around you that the shaft or rotating part is still moving but the strobing light makes it “appear” to be stopped. When tuning the stroboscope there are several times when the object will appear to be stationary. The highest CPM/RPM giving a single image is the exact running speed. Always check the drive unit name plate to confirm the actual running speed range. Other single images will occur at sub‐harmonic rates (i.e. 1/2 x, 1/4x, 1/8x running speed). Similar images can be seen by tuning to harmonics of operating speed (i.e. 2x, 4x, 8x, running speed). If looking at a shaft with one key way, tuned to 3x running speed or the 3rd harmonic, three keys will be visible. It is important that you find the fundamental operating frequency for most inspection techniques.

Triggering a Stroboscope

A stroboscope can be triggered typically from a TTL pulse signal. When the pulse hits the input the stroboscope will flash. Various sensors and vibration analyzers can provide this type of pulse. When the stroboscope is triggered externally, the flash rate and phase will automatically be synchronized with the trigger signal. Monarch Instrument can provide Remote Optical Sensors, Magnetic Sensors and even Laser Sensors to trigger our Stroboscopes.

Phase Shifting

Internal phase shifting is a feature used on advanced Stroboscopes which allows the user to visually shift a reference mark to a different viewing position. This technique is useful when the reference mark is hidden or obstructed. Moving the reference mark is usually accomplished via a jog button which relocates the image.

External phase shifting allows the tracking of variable speed machinery. External phase shift also allows a fixed delay in rotational degrees or time (usec). The stroboscope flash is being delayed from an external trigger signal. This feature is used to look at an instant of a cyclical operation that differs from the timing of the trigger signal. For instance you may be triggering off an engine at Top Dead Center (TDC) and the valves are open. If you wish to see the valves closed, you can shift the phase 180 degrees with the electronics of the Stroboscope.

Selecting a Stroboscope

Chose the type of power: AC or re‐chargeable batteries. When selecting a Stroboscope, consider the speed of the equipment you wish to observe, the type of environment, how bright the light should be and the triggering options. As just discussed, consider the need for phase shifting. Do you need the stroboscope to function as a tachometer with an external sensor? To see the entire line of Monarch Instrument digital stroboscopes contact us online, call our U.S. offices at 603‐883‐3390 or use our FAX: 603‐886‐3300.

Summary

This article does not even begin to outline all the uses of the Stroboscope in both maintenance and production. Stroboscopes can be used with video inspection systems for high speed packaging, with vibration data collectors to provide phase studies and operational deflection shape (ODS) analysis, to aid in dynamic balancing and the list goes on. The Stroboscope is a very cost effective maintenance and quality assurance tool. It can save you time and money while providing real‐time information in a safe and repeatable method.